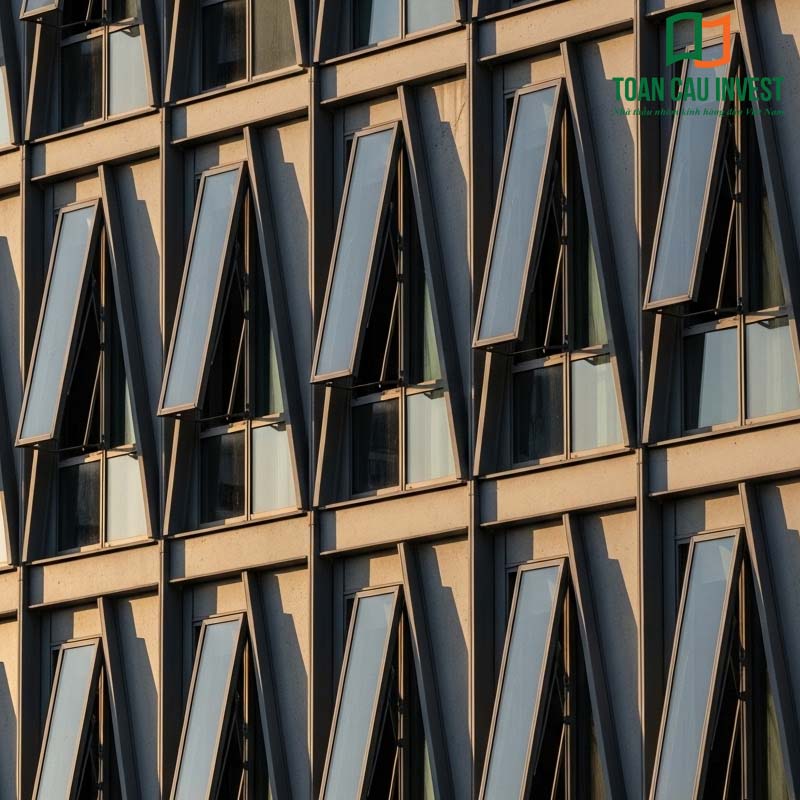

Awning aluminum glass windows are an optimal solution for buildings that require high standards in natural ventilation, daylight access, and airtightness. With a modern top-hinged design, this window system is not only ideal for townhouses and villas but also widely applied in office buildings, schools, and hospitals. From technical structure and material selection to installation methods, every element must be carefully considered to ensure long-term durability, aesthetic harmony, and investment efficiency

I. What Is an Awning Aluminum Glass Window?

An awning aluminum glass window is a type of window designed with a top-hinged mechanism that opens outward from the bottom, forming a fixed angle-typically between 30 to 45 degrees-from the wall surface. Its defining feature lies in the hinge placed at the top edge, while the bottom is pushed outward using a support arm or hydraulic stay, creating an “A” shape when viewed from the side. This design is optimized for natural ventilation while maintaining safety, even during light rain conditions.

In modern architectural projects, awning aluminum glass windows are commonly installed in fixed ventilation and lighting zones such as laundry rooms, bathrooms, kitchens, hallways, or skylight areas. Thanks to their “partially open – zero clearance” feature, they do not intrude into interior or exterior spaces, making them particularly suitable for compact layouts or projects that emphasize minimalistic aesthetics.

In terms of operation, when the user gently pushes the bottom frame, the support arm automatically lifts and locks the window at a fixed opening angle. Accessories such as the A-type stay arm, friction hinge, limit lock, and safety catch are all designed as an integrated system to ensure smooth, long-lasting operation especially in high-humidity environments or areas exposed to frequent weather changes.

Unlike casement or sliding windows, an awning aluminum glass window does not open the full 100% of the frame. However, it provides continuous airflow without interfering with the surrounding space. Compared to folding-sliding windows, the A-frame design may appear simpler but offers superior airtightness, water resistance, and ease of maintenance particularly when installed with proper techniques and paired with high-quality hardware systems.

In technically demanding projects such as west-facing villas, office towers, or modern townhouses, choosing awning aluminum glass windows goes beyond just ventilation it reflects a design mindset that values optimization, proper material understanding, targeted usage, and long-term performance assurance.

II. Structure of Awning Aluminum Glass Windows

To ensure stable, durable performance that meets the specific requirements of each project, selecting the right structure for an awning aluminum glass window is critical. This type of window is not merely composed of an aluminum frame and glass it is a coordinated system that includes a technical aluminum profile, safety glazing, specialized hardware, and sealing components.

Technical Aluminum Frame

The aluminum frame plays a foundational role in the construction of an awning aluminum glass window, directly influencing load-bearing capacity, airtightness, and overall lifespan. Typically, this window type uses a slim profile system with deep internal chambers that maintain rigidity even when only partially opened. Depending on the design requirements, developers can choose standard profile systems such as series 55, 60, or premium aluminum profiles with wall thicknesses ranging from 1.4mm to 2.0mm.

Aluminum systems used for awning windows must include internal reinforcement ribs to prevent twisting or deformation during operation. Additionally, the surface of the aluminum is often treated with anodization or exterior-grade powder coating to enhance corrosion resistance and maintain color durability under direct exposure to rain and sunlight.

Glass Panel

The glass component of an awning aluminum glass window typically consists of a fixed, small-sized pane, making it essential to choose glass types that offer high durability and safety especially for elevated positions or moisture-prone areas.

Depending on the intended use, several glass options can be considered:

-

8-10mm tempered glass: a popular and cost-effective option, offering excellent impact resistance.

-

6.38-8.38mm laminated safety glass: designed to minimize shard dispersion in case of breakage, enhancing occupant safety.

-

Double-glazed insulated glass units: improve thermal and acoustic insulation, ideal for high-rise buildings or street-facing villas.

The glass panel not only allows natural light into the space but also contributes significantly to the window’s visual expression. For this reason, many modern architects prefer to use low-E glass, reflective glass, or colored/tinted glass to ensure aesthetic coherence with the building’s overall façade design.

Integrated Hardware System

One of the key factors determining the operational performance of an awning aluminum glass window is the use of a fully integrated hardware system. Due to its unique top-hinged, outward-opening design, this window type requires specialized hardware entirely different from those used in casement or sliding windows.

Key components include:

-

A-type stay arm (friction arm): This component holds the sash at a fixed open angle. It is recommended to use units made of 304 stainless steel or solid die-cast aluminum alloy to prevent corrosion, especially in moisture-prone areas like kitchens and bathrooms.

-

Top hinge: Usually a long-axis sliding hinge mounted onto the aluminum frame, designed to bear the full weight of the sash. The quality of this hinge directly affects the durability and smooth operation of the window mechanism.

-

Locking system and safety latch: Unlike conventional handles, awning windows typically use specialized latches or flip-locks to secure the sash in the closed position and prevent accidental opening.

All hardware components must be precisely installed in accordance with technical drawings and be fully compatible with the selected aluminum profile system. This ensures proper alignment, prevents misoperation, and maintains the integrity of the opening-closing mechanism.

Gasket and Silicone Sealant System

Although often overlooked, EPDM gaskets and silicone sealants are crucial components in an awning aluminum glass window, especially for projects requiring excellent water resistance, wind protection, and sound insulation.

EPDM gaskets should be extrusion-molded to fit the groove, with high elasticity, UV resistance, and long-term weather durability without aging or cracking.

Silicone sealant must offer strong adhesion, withstand temperature variations, and remain intact over time. In high-moisture areas like bathrooms or toilets, it is advisable to use neutral-cure, moisture-resistant silicone (such as Sunseal S500 Pro or S600) to ensure a lasting bond between the aluminum frame and the glass panel.

This component also reflects the professional execution capabilities of the aluminum contractor. Using the correct type of sealant, applying it properly during corner crimping or glazing, and following best-practice procedures will ensure optimal airtightness preventing issues such as water ingress, air leakage, or whistling wind noises.

III. What Factors Affect the Cost of Awning Aluminum Glass Windows?

The cost of installing awning aluminum glass windows is influenced by much more than just size or design it is the result of multiple technical considerations, including the aluminum profile system, hardware selection, and installation requirements. For high-end projects, A-type outward-opening windows are often chosen after careful evaluation to ensure alignment between functionality and architectural aesthetics.

Type of Aluminum System Used

Each aluminum profile system whether Series 55, Series 60, or imported options varies significantly in price. High-end architectural-grade systems from well-known brands like XINGFA, Hopo, or custom systems tailored to project-specific standards typically feature profile thicknesses above 1.4mm, with anodized or premium powder-coated finishes. These features not only enhance performance but also add to the overall unit cost of the window.

Type of Safety Glass Used

Glass specification has a major impact on total cost. For awning aluminum glass windows, the choice between 8-10mm tempered glass, laminated safety glass, or double-glazed insulated glass units (IGUs) will lead to noticeable price variations. Projects requiring high noise reduction and thermal insulation often prefer double-glazed units with inert gas filling, which are significantly more expensive than standard single-pane glass.

Integrated Hardware and A-Type Friction Arms

This type of window requires a specialized hardware system, including awning hinges, hydraulic stays, and locking latches. Using high-quality, brand-name hardware from Kinlong, Draho, Roto, or Hopo adds to the total cost compared to generic options. Additionally, hardware compatibility with the selected aluminum system plays a role in determining the final unit price.

Size and Quantity of Windows in the Project

Larger windows require more robust structural reinforcement. For awning openings wider than 1000mm, frame systems must be recalculated to ensure stability at a 45-degree open angle. Moreover, projects with a larger number of windows may benefit from adjusted unit pricing based on overall scale (common in large developments).

Fabrication, Transportation, and Installation Logistics

Installation and manufacturing costs vary by project location. For instance, high-rise urban projects often involve additional expenses for scaffolding, hoisting equipment, and labor safety leading to higher installation costs than low-rise residential buildings. Remote or hard-to-access locations may also incur extra transportation and labor travel fees.

Custom Technical Requirements from Investors

Some projects may require certified safety glazing, storm-resistant frames, or corrosion-proof hardware for coastal areas. These specifications are typically itemized separately in cost estimates. For large-scale contractors or developers, detailed quotations must often include technical specifications, construction drawings, and material submittals tailored to project-specific performance criteria.

IV. Real-World Applications of Awning Aluminum Glass Windows Across Project Types

Awning aluminum glass windows are not only ideal for residential buildings but are also widely adopted across a diverse range of construction types, thanks to their compact design, effective natural ventilation, and high durability. At Toàn Cầu Invest, this window solution has been successfully implemented in numerous high-rise developments, government buildings, and urban complexes where high standards of ventilation, safety, and long-term performance are required.

Villas and Resorts

In suburban villas and resort-style developments, awning windows are typically installed in bathrooms, corridors, skylights, or the rear façade- providing continuous airflow while maintaining the overall architectural aesthetics.

Notable Projects:

-

Hoa Anh Dao Villas – Vincom Long Biên

-

Casamia Hoi An, La Celia City, Villas in District 2 – Ho Chi Minh City

-

Flamingo Dai Lai Resort, Flamingo Tan Trao, Flamingo Hai Tien

These projects required a refined integration of awning aluminum glass windows with large fixed glass panels creating private yet naturally ventilated environments, a hallmark advantage of this window type.

High-Rise Apartments and Mixed-Use Residential Complexes

In high-rise apartment settings, traditional window types may pose safety risks due to high wind loads or limited balcony/loggia space. Awning windows offer a safe and effective solution for maintaining airflow, particularly in bathrooms, laundry areas, or narrow vertical glazing panels near the ceiling.

Representative Projects:

-

Ecohome 3, Ecohome Phuc Loi – Thu Do Invest

-

Mipec Xuan Thuy, Mipec Rubik, Royal Park – Bac Ninh

-

The Arena Cam Ranh, Calla Apartment – Quy Nhon

-

Apec Mandala Wyndham – Phu Yen, Apec Diamond Park – Lang Son

-

D’.Palais De Louis, D’.Le Roi Soleil – Tan Hoang Minh Group

-

Danko City – Thai Nguyen (318 units)

These projects demand a fully integrated aluminum-glass façade system. The application of awning aluminum glass windows enhances natural ventilation, reduces reliance on mechanical air systems, and complies with premium handover standards for high-end apartment units.

Offices and Government Buildings

In office towers and administrative facilities, awning aluminum glass windows are typically applied in technical rooms, stairwells, restrooms, or corridor ventilation areas where limited, safe openings are required without disrupting internal circulation.

Application Projects:

-

Headquarters of the Southern Border Guard Command

-

S4-S7 Mine Action Center

-

Long Thanh Administrative Office – Dong Nai

-

Van Phu Office, Phuong Thai Office Building

In these projects, awning windows are equipped with synchronized accessories and anti-corrosion powder-coated finishes ideal for specialized work environments with strict maintenance and durability requirements.

Hospitals and Educational Facilities

For public-use buildings such as hospitals and schools where constant air circulation is necessary but safety must be guaranteed awning aluminum glass windows are virtually mandatory.

Executed Projects:

-

Nam Dinh General Hospital (700 beds), Hanoi Pediatric Hospital

-

Cau Giay Experimental School, East Asia University of Technology Bac Ninh

-

People’s Police Academy of Political Science

These windows are designed to provide acoustic insulation, wind resistance, and are installed with imported high-performance hardware meeting strict operational safety standards for long-term use.

V. Toan Cau Invest – Top 10 Aluminum and Glass Contractors in Vietnam

With over 13 years of experience in the architectural aluminum and glass industry, Toan Cau Invest is a pioneer in the design, manufacturing, and installation of awning aluminum glass windows for premium projects nationwide. Beyond high product quality, Toan Cau is recognized for its in-depth technical expertise, synchronized production lines, and a seasoned team of engineers with extensive on-site experience.

In-House Production Capacity

Toan Cau Invest operates a high-capacity aluminum and glass manufacturing facility equipped with synchronized production lines and precision CNC machinery. By actively controlling the production of aluminum profiles, glass units, and custom hardware tailored to each project’s technical requirements, we ensure both supply schedule and strict input quality control.

Experienced Engineering and Installation Team

Our workforce comprises highly qualified engineers, architects, and site managers who have successfully executed aluminum-glass packages for public-sector buildings, high-end urban developments, Grade-A office towers, and commercial centers. The installation process strictly adheres to ISO standards and occupational safety regulations, ensuring every project meets international quality and safety benchmarks.

Comprehensive Aluminum and Glass Solutions – Optimized for Every Type of Project

At Toan Cau Invest, we go beyond traditional facade glazing and aluminum door systems. Our expertise spans across a wide range of advanced solutions, including swing doors, sliding-folding doors, fire-rated systems, curved glass walls, structural glass partitions, and awning aluminum windows meeting diverse architectural and functional requirements across all project types.

Commitment to Quality and Long-Term Support

All aluminum and glass products installed by Toan Cau Invest undergo rigorous quality control and handover inspections in full compliance with applicable standards. We offer extended warranties as specified in project contracts, and our dedicated after-sales support team is always ready to provide on-site technical assistance nationwide for large-scale developments.

With over 13 years of hands-on experience in manufacturing and installing synchronized aluminum-glass systems, Toan Cau Invest proudly partners with investors, general contractors, and architects to bring modern and sustainable building designs to life.

We deliver technically certified Awning Aluminum Glass Window Solutions – meeting architectural aesthetics, performance expectations, and construction standards.

Contact Toan Cau Invest today to:

-

Receive expert consultation tailored to your project type

-

Access our full product catalogue, material samples & detailed shop drawings

-

Schedule a site survey & obtain a customized quotation

Hotline: 0902 50 1185 – 0902.168.238

Email: contact@toancauinvest.vn

Website: www.toancauinvest.vn

Tiếng Việt

Tiếng Việt 한국어

한국어 中文 (中国)

中文 (中国) ພາສາລາວ

ພາສາລາວ ភាសាខ្មែរ

ភាសាខ្មែរ