Today, Aluminum-glass design is no longer considered a secondary finishing element but a strategic component in modern architecture. Contemporary projects demand materials that are not only aesthetically refined but also high-performing, sustainable, and compliant with green building standards.

This article highlights five key trends in Aluminum-glass design for 2025 providing a solid foundation for investors, architects, and general contractors to define the right solutions from the early design phase.

I. When Aluminum-glass design is no longer just “finishing work”

Traditionally, Aluminum-glass design was regarded as a late-stage finishing task in the construction process. However, from 2024 onward and especially in 2025 aluminum and glass have moved to the center stage: shaping a building’s aesthetic identity, influencing operational performance, and becoming a strategic factor in modern architectural design.

This transformation is far from coincidental. Instead, it reflects an irreversible shift: investors and architects increasingly prioritize materials that combine aesthetics with long-term performance, while meeting green building and energy-efficiency standards.

Within this context, aluminum and glass emerge as pioneering materials not only for their flexibility, but also for their ability to integrate advanced technical solutions seamlessly into architectural projects.

In large-scale projects such as office towers, mixed-use commercial complexes, luxury hotels and resorts, or contemporary villas, Aluminum-glass design is increasingly integrated from the earliest architectural concept stage. Critical factors such as glass performance metrics (U-value, SHGC), aluminum system selection, synchronization between façades and window-door systems, feasibility of high-rise installation, and environmental sustainability are analyzed in parallel with architectural ideas right from the beginning.

This shift introduces a new demand: it is no longer about simply selecting aluminum-glass products, but about choosing a comprehensive Aluminum-glass design solution an integration of materials, systems, installation technologies, and long-term operational performance. This approach is particularly crucial for projects built to international standards such as LEED, EDGE, or ESG-ready developments.

For contractors, aluminum-glass specialists, and fabrication workshops, this evolution sets higher requirements in terms of technical expertise, system integration, and early-stage solution consulting rather than merely executing based on pre-prepared drawings.

II. Five trends shaping Aluminum-glass design in 2025

The 2025 market marks a decisive shift in how Aluminum-glass design is approached moving away from selecting single materials toward integrated, system-based solutions. Below are five major trends that investors, architects, and general contractors should carefully consider to ensure their projects remain both modern and sustainable.

1. Smart aluminum-glass façades: Optimizing building performance

One of the most significant changes in Aluminum-glass design is the rise of smart façade systems, particularly Unitized and Semi-Unitized solutions. These systems are widely adopted in high-rise office buildings, shopping malls, and luxury hotels thanks to their fast installation, uniform quality, high airtightness, and simplified maintenance.

When combined with advanced glass types such as Low-E, Solar Control, reflective, or electrochromic glass, façades evolve into “intelligent shields” that minimize energy loss and enable projects to meet stringent green building standards like LEED, EDGE, or WELL.

This is not merely a technical trend it is becoming a mandatory requirement for ESG-oriented developments or commercial projects with long-term operational goals.

2. Open spaces with large glass walls – Creating depth and architectural connection

As modern architecture shifts toward minimalism, spatial connectivity, and optimization of natural light, large-scale glass wall systems have become a core solution in Aluminum-glass design. In luxury villas, penthouses, resorts, or automotive showrooms, features such as floor-to-ceiling glass panels, oversized glazing, or frameless systems are not only aesthetic highlights but also expand the sense of space, enhance visual experience, and reduce reliance on artificial lighting.

These façade systems are often paired with slim-profile yet high-strength aluminum frames, ensuring structural safety while maintaining clean, minimalist lines. This makes them a preferred choice among architects aiming to embody the design philosophy of “architecture in harmony with nature.”

3. Slim yet high-strength aluminum-glass doors – Minimalist but optimized

In 2025, premium Aluminum-glass design for door systems is moving strongly toward minimalism. Frameless sliding doors, oversized sliding panels, and thermally broken folding systems all demonstrate an effective balance between architectural aesthetics and functional performance.

Slim aluminum frames engineered with advanced structural design allow for greater glass surface area-expanding views while still meeting stringent safety and rigidity standards. This trend is particularly well-suited for coastal developments, luxury villas, and modern urban residences.

4. Eco-friendly materials – The choice for green and sustainable buildings

In Aluminum-glass design, the concept of “sustainability” goes beyond material durability; it also refers to the material’s contribution to a project’s environmental strategy. By 2025, internationally funded developments or projects pursuing green certifications are required to meet strict criteria regarding material sourcing and lifecycle performance.

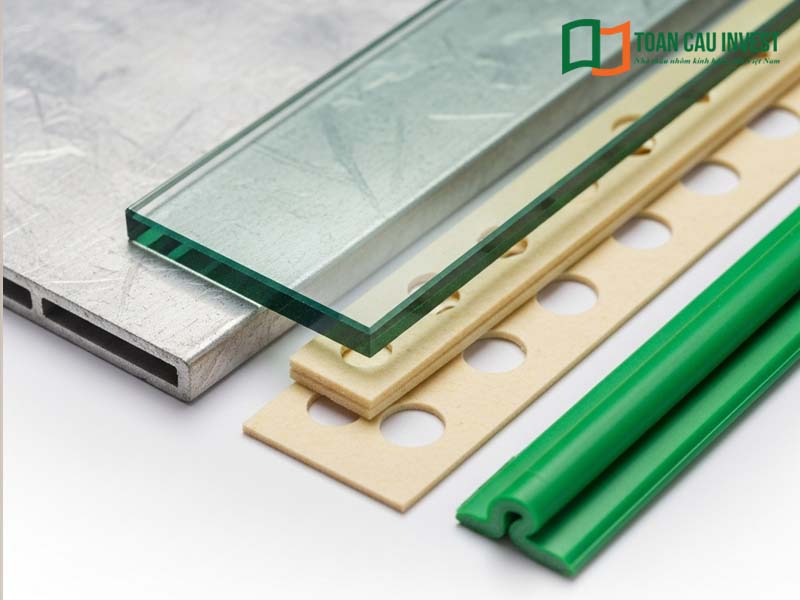

Recycled aluminum that meets industry standards, multi-layer safety glass, non-toxic EPDM gaskets, and lead-free silicone sealants are becoming mandatory choices. These materials not only reduce CO₂ emissions during manufacturing but also allow for disassembly and reuse during renovations or functional conversions optimizing the long-term investment lifecycle of the building.

5. Integrated aluminum-glass solutions – Optimizing cost, schedule, and quality

Another key trend in Aluminum-glass design is the shift from purchasing separate components to adopting fully integrated system solutions. In practice, this means using a single, unified aluminum-glass system for façades, doors, windows, balustrades, shower enclosures, and glass staircases designed, manufactured, and installed by one provider.

Early-stage integration delivers multiple advantages:

-

Unified design language, enhancing the overall architectural aesthetics.

-

Shortened construction timelines, minimizing material and technical conflicts.

-

Simplified quality control and maintenance throughout the building’s lifecycle.

Contractors with end-to-end capabilities in manufacturing, engineering, and turnkey installation will become strategic partners for general contractors—particularly in EPC and Design & Build projects.

See Also: Guide to Selecting Aluminum-Glass Doors for Different Types of Projects

III. Strategic recommendations for investors and architects in 2025

In an increasingly competitive materials and construction market, staying updated with design trends is no longer a competitive edge but a baseline requirement for creating buildings with long-term functional, commercial, and sustainable value. Particularly with aluminum and glass one of the defining architectural materials of our era strategies for selection and application must be defined as early as the conceptual design stage.

Below are four strategic directions that investors and architects should consider when implementing Aluminum-glass design in projects from 2025 onwards:

1. Integrate Aluminum-glass design from the concept stage – Avoid leaving it until finalization

A common mistake in many projects is treating aluminum-glass systems as a “later stage” element, which often results in design conflicts, reduced aesthetics, and poor performance optimization. In contrast, premium developments are now integrating Aluminum-glass design right from the architectural concept phase to ensure alignment across:

-

Overall architectural language,

-

Façade proportions,

-

Natural lighting and ventilation strategies,

-

Material performance and efficiency.

Façade systems, large-span glazing, slim-profile doors, or Unitized assemblies all have unique technical requirements that must be addressed early to achieve optimal construction efficiency and long-term operational performance.

2. Prioritize integrated aluminum-glass systems – Reduce operating costs, increase long-term value

Instead of sourcing separate products such as doors, partitions, or balustrades from multiple vendors, the 2025 trend in Aluminum-glass design emphasizes using fully synchronized systems. Employing one aluminum system, one accessory system, and one gasket & sealant system ensures:

-

Significant reduction in maintenance and repair costs after handover,

-

Elimination of conflicts in material compatibility, color inconsistencies, and mismatched locking or sliding mechanisms,

-

Enhanced project value in the eyes of clients and operators, thanks to smooth operation, cohesive finishing, and easy replacement of components when needed.

For commercial developments, hotels, showrooms, or resort villas, system uniformity in Aluminum-glass design not only enhances user experience but also strengthens brand value and positioning.

3. Choose partners with the capability to provide end-to-end solutions

For landmark or large-scale projects, simply purchasing materials from a distributor is no longer sufficient. Investors and design firms need to collaborate with aluminum-glass providers that possess real technical execution capacity, including:

-

Ability to analyze design concepts and provide consultancy from the early stages,

-

R&D teams with deep knowledge of façade systems, load-bearing door structures, acoustic and thermal solutions,

-

In-house production systems capable of controlling both quality and schedule,

-

Proven construction experience with premium aluminum-glass systems such as Unitized, Slimline, and thermally broken solutions.

Selecting the right partner minimizes technical risks, accelerates project delivery, and safeguards investor interests throughout the entire building lifecycle.

4. Make “performance and sustainability” the foundation of design

While aesthetics remain essential, in 2025 and beyond, performance metrics and material durability are becoming top priorities especially for projects seeking green building certifications or attracting international investment.

In Aluminum-glass design, internal benchmarks should include:

-

Glass performance values such as U-value, SHGC, and Tvis,

-

Material recyclability (e.g., recycled aluminum, multi-layer safety glass),

-

Airtightness, water resistance, and wind-load resistance up to level 12,

-

System integration and ease of maintenance after handover.

The earlier these performance and sustainability criteria are built into the design process, the better investors can control lifecycle costs while creating a competitive edge for sales, leasing, or long-term operations.

IV. Toàn Cầu Invest – Strategic partner for modern and sustainable Aluminum-glass design

As the construction industry moves toward high-performance architecture, sustainable materials, and integrated solutions bridging design, materials, and execution, choosing the right aluminum-glass partner is no longer about hiring an installer it is about securing a strategic ally for the entire project lifecycle.

Toàn Cầu Invest is among the few companies in Vietnam capable of delivering comprehensive Aluminum-glass design solutions: from material consultancy and technical design, to in-house manufacturing, on-site installation, commissioning, and post-handover maintenance.

1. Engaging from the preliminary design stage – Optimizing solutions from the drawing board

With hands-on experience across hundreds of projects and a team of highly specialized engineers, Toàn Cầu Invest actively participates from the concept design phase helping architects and investors optimize aluminum-glass systems to match the unique requirements of each project.

We go beyond supplying product specifications by proactively:

-

Analyzing and proposing façade solutions (Unitized, Semi-Unitized, Stick) based on building height, wind conditions, and aesthetic requirements,

-

Advising on aluminum-glass door systems best suited for specific climates and functions (villas, hotels, hospitals, factories, etc.),

-

Recommending integrated solutions for doors, windows, glass partitions, balustrades, and shower enclosures to ensure cohesive architectural language,

-

Simulating aluminum-glass performance with specialized software such as THERM and WINDOW, supporting validation of U-value, SHGC, light transmittance, and acoustic insulation.

These specialized services set Toàn Cầu Invest apart from traditional contractors, particularly at the design–engineering integration stage, where most suppliers cannot provide deep technical collaboration.

2. In-house production – Aluminum-glass design – execution – full-process quality control

Toàn Cầu Invest owns a dedicated aluminum-glass fabrication facility, fully equipped with CNC machinery, cutting systems, corner pressing, hardware assembly, and airtightness testing chambers that meet international pressure standards.

On-site construction is managed through a rigorous 4-step workflow:

-

Site survey and 3D façade measurement,

-

Development of shop drawings with detailed specifications for each aluminum-glass system,

-

In-house fabrication and assembly, ensuring module-by-module quality control,

-

Transportation and installation by our internal technical team without reliance on outsourced labor.

Our commitments include:

-

Water resistance, airtightness, and wind-load compliance in line with both TCVN and equivalent international standards,

-

High precision in dimensions, aesthetics, and architectural proportions as per original design,

-

On-time handover with complete acceptance documentation and transparent warranty.

What truly differentiates us is our ability to self-manage the entire Aluminum-glass design and execution process, avoiding dependence on fragmented subcontractors a common cause of technical errors, delays, and lack of system consistency in many current projects.

3. Integrated Aluminum-glass design – The premium advantage for high-end projects

One of Toàn Cầu Invest’s standout strengths is the capability to deliver cohesive Aluminum-glass design solutions across the entire building envelope and interior:

-

Large-format glass façades for shopping malls and office towers,

-

Slimline aluminum doors for luxury villas,

-

Transparent glass balustrades ensuring both safety and aesthetics for high-rise balconies,

-

Shower enclosures and interior glass partitions for hotels and resorts.

Adopting a unified material and execution system brings clear benefits:

-

Easier quality and color control, ensuring consistent architectural aesthetics,

-

Faster construction timelines with fewer inter-trade conflicts,

-

Enhanced architectural value and long-term performance for the entire project.

4. Proven credibility through landmark projects

Toàn Cầu Invest’s capabilities are not only theoretical but also demonstrated through numerous large-scale, technically demanding, and time-sensitive projects, such as:

-

Quảng Ninh Provincial Police Headquarters: Unitized glass façade with high wind resistance and acoustic performance,

-

Long Thành Administrative Center (Đồng Nai): large-span glass façades and premium soundproof aluminum doors,

-

Danko City (Thái Nguyên): complete aluminum door and glass balustrade systems for hundreds of villas and shophouses.

In addition, we have delivered a wide portfolio of high-profile projects across Vietnam, including:

-

Flamingo Tân Trào (Hotel Complex),

-

Ba Sao Project – Hà Nam,

-

Flamingo Hải Tiến,

-

Nam Định General Hospital, Hanoi Children’s Hospital,

-

The Arena Cam Ranh, Apec Mandala Wyndham Phú Yên,

-

Royal Park Bắc Ninh, Apec Diamond Park Lạng Sơn,

-

Mipec Xuân Thủy, Mipec Rub, Ecohome 3,

-

And many other office buildings, hotels, and premium residences nationwide.

Investors highly appreciate the professionalism, proven technical expertise, and especially the ability of Toàn Cầu’s engineering team to resolve on-site technical challenges with precision and efficiency.

If you are seeking a partner capable of providing comprehensive Aluminum-glass design solutions from consulting, engineering, and production to full-scale execution for high-end projects, Toan Cau Invest is ready to accompany you at every stage, from concept to completion.

Contact our technical team today for in-depth consultation and a free on-site survey.

Hotline: 0902 50 1185 – 0902.168.238

Website: www.toancauinvest.vn

Office Address: LK 12 – 31, Van Khe New Urban Area, La Khe Ward, Ha Dong District, Hanoi, Vietnam.

Tiếng Việt

Tiếng Việt 한국어

한국어 中文 (中国)

中文 (中国) ພາສາລາວ

ພາສາລາວ ភាសាខ្មែរ

ភាសាខ្មែរ